Defense & Security

ALCEN has been a key supplier of French strategic defense for over twenty years. The group also manufactures equipment for French National Navy vessels and is a leader in active imaging and other technologies.

ALCEN has been a key supplier of French strategic defense for over twenty years. The group also manufactures equipment for French National Navy vessels and is a leader in active imaging and other technologies.

Vision, Inspection & Localization

Some of our relevant subsidiaries:

-

read more

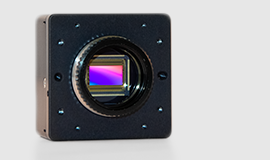

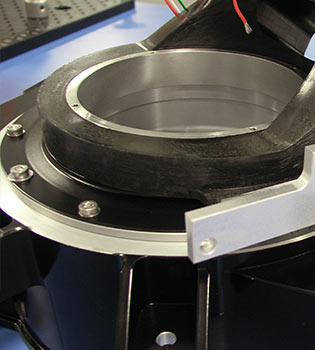

With over 30 years of experience, LERITY (formerly LHERITIER) designs and manufactures complex cameras and vision systems, capturing images in the visible spectrum. Thanks to an ambitious policy of research & development, notably in the field of sensors and algorithms for real-time image enhancement, LERITY has reached a level of excellence in image restitution quality, and is today a recognized expert in low light levels.

LERITY is both an OEM for important international actors in optronics & vision systems and an optronics company in itself at the forefront of innovation, notably in active imaging technology via its CAT EYE camera and CAT EYE series of vision systems. LERITY can easily and fluidly adapt itself to the specific needs of its customers: whether they be industrials, security companies or military forces.

Its reputation has notably been established in 3 markets, both in France and internationally:

- Defense & Security: Day channel for vehicle-mounted optronics system, perimeter vision and wide area surveillance, cameras for submarine periscope, day/night coastal surveillance, shooting range metrology, day/night vision cameras with CAT EYE active imaging

- Aeronautics: Head-up display cameras (HUD), taxiway cameras, cargo-monitoring cameras, cockpit cameras (CIRS)…

- Railway: On-board retrovision systems (SNCF), guidance for tramways and buses, camera assistance in automatic driving

- Website

- Location on map

- +33 1 34 24 38 20

LERITY on ALCEN's website

Defense & Security Vision, Inspection & Localization

Defense & Security Engineering, Maintenance & Services

Energy Nuclear

Aeronautics & Space Vision & Inspection

CAT EYE XLR

Identify a vehicle or vessel at up to 20 kilometers away in pitch black or conditions of low visibility

The CAT EYE XLR is a fixed day/night vision system with high performance extra-long-range observational capacity, challenging the world of infrared and previously-available nighttime identification capabilities for defense and security forces.

This system renders a 24/7 flux of video in FULL HD, providing even more pixels and increasingly more visibility than its field-proven CAT EYE predecessors. CAT EYE XLR provides crisp, natural vision in the visible spectrum from daylight to the dark of night, making it possible to identify a vehicle or vessel at up to 20 kilometers away in pitch black or conditions of low visibility. Its daytime range of vision is 40 kilometers when the system is mounted at an elevated position.

Range-gated active imaging is the mode allowing for target identification in the dark of night and this is a technology in which LERITY possesses true expertise; Active Imaging also provides improved quality of vision in rain, snow, fog, heavy pollution or even sandstorms. The CAT EYE XLR’s 200 W laser sources, illuminating the target with one thousand pulses of light per millisecond, are divided into two fields of illumination: narrow and ultra-narrow, to allow for precise target designation.

All the features of a ruggedized and modern surveillance camera (gyro-stabilized turret, telemetry, GPS, recording and playback on control screen…) make this technological jewel an unparalleled asset for coastal surveillance, border surveillance or perimeter surveillance, and for the protection of critical infrastructure (nuclear parks, oil facilities, and more).

Since the launch of the product line in 2015, CAT EYE vision systems have received very positive feedback from homeland security and military forces. They are the subject of extensive testing campaigns and have been integrated as security solutions in several countries including France. The development of the CAT EYE XLR is supported by the French Navy. It is compatible with various sensors (Radar, AIS...) and can be integrated with various C2 command systems.

HEMISPACE

360° detection, localization and tracking of UAVs

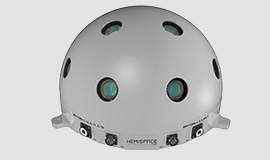

HEMISPACE, a hemispheric optronic imaging system, is a state-of-the-art vision system designed by LERITY for the 360° detection, localization and tracking of UAVs. Composed of 12 very high-resolution cameras evenly distributed across a half-sphere structure, HEMISPACE ensures full-sky coverage and the rapid detection of any flying object including micro-UAVs measuring 30 cm × 30 cm. Each of the 12 cameras can detect and track up to 10 targets, for a total of 120 possible threats processed by HEMISPACE. This allows for effective surveillance against the topical threat of both single drones and drone swarms, increasingly used for hostile purposes.

Multiple HEMISPACE systems can be combined in a network for increased coverage of the detection zone (up to 6 km), interconnected either by a private and secure IP network or by wireless communication (secure 3G/4G/5G). This mesh of HEMISPACE makes it possible to triangulate data in order to measure the distance of the potential drone threats from the site under HEMISPACE protection.

HEMISPACE can be implemented both at night and during the day, including in glaring sun, rain, fog and other difficult environments thanks to its robust sensors and high-performing algorithms. Two modes, passive and active, allow the operator working at night to choose when to illuminate the sky around the system with HEMISPACE’s embedded light sources (emitting flashes of light lasting just tenths of a millisecond, in order to preserve stealth). The entire system can be illuminated or the illumination can be implemented by sector.

HEMISPACE is operable 24/7 with a command and restitution GUI (Graphic User Interface). The operator chooses to view an image of the target by clicking on the dots representing the target. The real-time visualization of the target allows for quick decision making in the face of potential danger.

HEMISPACE is transportable and can be quickly deployed. It can also be connected to other sensors or equipment, making up a global system in the fight against drones. HEMISPACE is suitable for the protection of military sites but also for the protection of civilian infrastructure such as airports, industrial facilities, power plants, sporting complexes and more.

Vision Systems

LERITY designs and manufactures HD cameras for installation on ground defense platforms or on surface vessels. Fitted with high-resolution sensors designed both for day (HD visible channel) and for night (intensified visible channel or low light level), LERITY cameras and vision systems are also extremely robust. Thanks to embedded image processing, LERITY systems provide reliable solutions that can be fully integrated into the client's architecture or structure.

Each year LERITY manufactures several hundred cameras, equipping the visible channels of major optronics equipment, installed on land vehicles or on fixed optronics platforms.

LERITY works with numerous vehicle manufacturers (Elbit, Renault Trucks, Nexter, Leonardo, Lockheed Martin, THALES, Safran, etc.) and equips the main test centres of the DGA (the Defense procurement and technology agency of the French government).

LERITY's cameras are deployed on the vessels the SSM Scorpène, the SNLE Barracuda, the SSM Sauro and their export versions, the submarines of the French and Italian Navies, and have a daily presence in every sea of the world.

Naval & Submarine

Some of our relevant subsidiaries:

-

read more

ALSEAMAR designs, manufactures and operates naval and underwater products (subsea gliders, unmanned surface vehicles, swimmer delivery vehicles, underwater acoustic positioning equipment, naval radio communication systems, deep-water pure syntactic foam buoyancy products) and is a provider of numerous services (underwater and marine monitoring, inspection, maintenance and upgrade of naval weapon systems, training, and more).

ALSEAMAR's commitment to its customers relies on the high skills and reactivity of its roughly 100 members of personnel, including over 50 engineers and 30 senior technicians, ready to be mobilized for projects around the world.

Main Product Lines

- Subsea and surface robotics

- Radio frequency communications

- Subsea passive acoustics

- Subsea vehicles for divers

- Deep-water syntactic foam buoyancy materials

Main Services

- Life-extension services for orphan and/or aged naval systems

- Marine survey services using subsea gliders and unmanned surface drones

- Localization of aircraft or submarine black boxes in the event of an accident at sea

- Training and instruction

ALSEAMAR on ALCEN's website

Defense & Security Naval & Submarine

Defense & Security Engineering, Maintenance & Services

Energy Oil & Gas

Aeronautics & Space Engineering & Maintenance

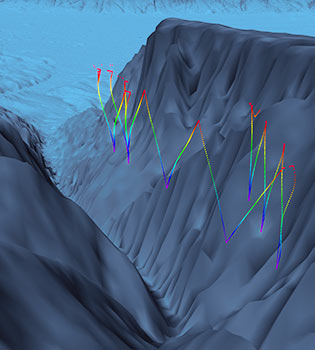

Acoustic Positioning System

ALSEAMAR designs and manufactures portable trajectography systems for devices moving under water, torpedoes or drones, under the GIB product line.

Consisting of a control unit and a set of buoys, they receive the signals transmitted by the acoustic transmitter mounted on the underwater device being tracked. The buoys measure distances and use a local radio network to periodically transmit their GPS position and the distances measured to a control unit installed on a support or land vehicle. This unit triangulates the positions of the underwater device and displays them on a map in real time and with great precision.

GIB portable trajectography systems are used by manufacturers in the naval sector to qualify their subsea machinery and by naval forces to train their crews and to intervene in the event of a stricken submarine in order to accurately locate it.

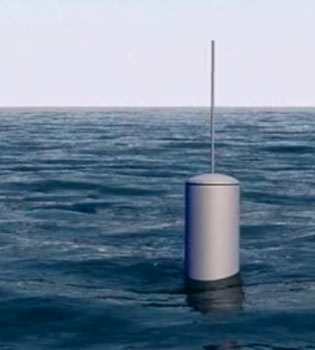

Expendable GPS/AIS Buoys for Submarine Communications

ALSEAMAR X-SUB buoys allow submarines to communicate with above the sea’s surface without raising a periscopic communications antenna. The submarine continues its course, undetectable at its operational depth.

The X-SUB buoy is a device released via the standard ejector (sippican). The buoy then rises to the surface and remains connected to the submarine by a wire connection.

The buoy acquires the GPS and the AIS positions, which are transmitted to the submarine. The GPS and the AIS positions are visible on board the submarine on a designated operating unit screen.

Once the wire connection is broken, the buoy automatically scuttles and sinks.

Manned Submarine Propulsion Vehicle

ALSEAMAR designs and manufactures subsea propulsion vehicles used to transport frogmen (2 to 6 combat divers— depending on the type of vehicle) during special operations: expansion of their scope of operations, strategic target attacks on land and at sea, infiltration or exfiltration of commando units, intelligence, surveillance and reconnaissance missions, and maritime counter-terrorism.

ALSEAMAR's manned submarine propulsion vehicles are ergonomic to avoid diver fatigue and have high endurance, navigation accuracy and communication and observation capabilities. They can be deployed from the shore, boats or submarines using a dry deck shelter. They have a large loading capacity and are easy to use.

Radio Communication Antenna System

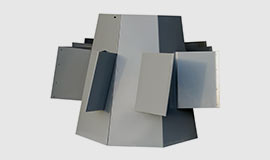

ALSEAMAR designs and manufactures multi-purpose submarine antennas covering a wide range of frequencies from VLF to UHF and equipped with satellite communication.

Installed in a particularly compact hoisting mast, the antennas enable the simultaneous emission and reception of several frequencies, despite their small size.

ALSEAMAR antennas are compact while ensuring high levels of performance and are particularly suited to the requirements of subsea communication.

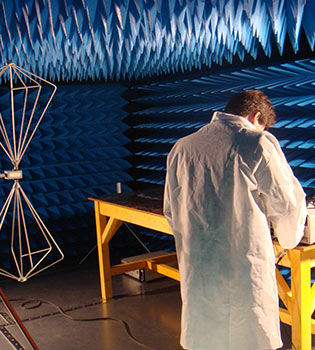

ALSEAMAR has long experience in the design, simulation, manufacturing and characterization of antennas for vessels (both active and passive antennas covering different frequencies: VLF/LF, HF, V/UHF, UHF) and high-performance multi-couplers to dispatch input/output signals. These antennas and multi-couplers can be used to create a subsystem of antennas for surface vessels that incorporate the most stringent radar cross-section reduction requirements.

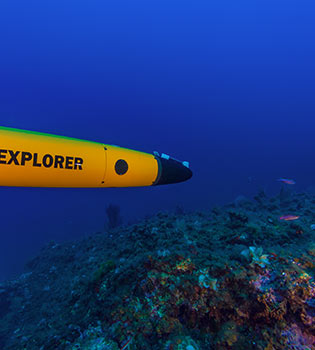

Subsea Glider

ALSEAMAR designs, manufactures and operates autonomous, high-endurance subsea drones: the SeaExplorer gliders.

Designed to collect data over large areas (thousands of kilometers), over long periods (months) and at great depths (up to 1,000 m), SeaExplorer gliders are propelled by buoyancy variation. SeaExplorer vehicles silently glide along the water column, collecting physical, chemical, biological and/or acoustic data, depending on the sensors installed. Their major added value lies in their low procurement and operating costs compared to the vessels or other means traditionally used for the same type of mission.

SeaExplorer gliders are easy to operate and can be deployed and recovered by a smaller crew, using small boats in coastal waters. Remotely controlled via satellite communication, they receive orders from the control PC at an ALSEAMAR site or at another designated site and transmit navigation information and collected data to land.

SeaExplorers are used by scientists and oceanographers, by environmental agencies responsible for protecting seas and oceans, by operators in the oil sector and by navies.

ALSEAMAR operates Gliders for its clients on a 24/7 basis and in every sea of the world.

Subsea Light Vehicles

The MURENE subsea light vehicles are a new grade of subsea diver propulsion systems. They have been designed to provide the best ergonomics and performance standards for combat swimmers. They can be deployed from the shore, a boat or submarine. A large cargo capacity, high navigation accuracy and excellent swimmer protection are the key strengths of these vehicles.

Equipped with the latest generation of fibre-optic gyroscope navigation systems combined with a DVL, the MURENE can lead offensive operations in coastal zones and shallow waters in order to neutralize maritime or land targets. Their small size and easy maneuverability make them the perfect tool to furtively approach targets as close as needed.

Simulation

Some of our relevant subsidiaries:

-

read more

With over 20 years of experience, ITOPP (formerly ITHPP) has become the French leader in high pulsed-power and high-power microwave technologies.

Driven by customer specifications, ITOPP designs and manufactures adapted and highly innovative systems linking these technologies to scientific research and also to civil and military applications.

High Pulsed-Power technologies allow for the amplification of electrical power delivery over a shorter burst period. Since energy is the product of power over time, by maintaining a constant flow of energy and reducing the duration of the pulse, it is possible to achieve powers in excess of one hundred Gigawatts.

High-Powered Microwaves are very highly charged electromagnetic pulsations capable of disturbing and even destroying electronic components used in today's increasingly complex systems. The interest in these high-powered microwaves are due to the vast array of uses, varying from more classic uses (such as Radar) to more advanced technologies, such as those used in Electronic Warfare.

- Website

- Location on map

- +33 5 65 33 43 30

ITOPP on ALCEN's website

Defense & Security Airborne drone

Defense & Security Simulation

Behavioral Studies of Materials Under Very High Pressures

ITOPP designs, develops and manufactures a line of generators to perform isentropic compression testing of materials.

As the only company in the world with this expertise, ITOPP is able to precisely study the behavior of materials subjected to extreme dynamic pressures, in particular the acceleration of projectiles to speeds in excess of 10 km/s, speeds inaccessible by other experimental means.

Due to its high-performing equipment and technologies, ITOPP is able to conduct research on the impacts of hyper-speeds that can be applied to the following fields:

- Defense & Security: Development of armor

- Space: Impact of micrometeorites on satellites

- The physics of explosives

- Materials research: Determining equations of state at extreme pressures (around a million bar)

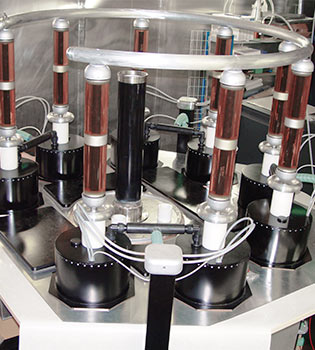

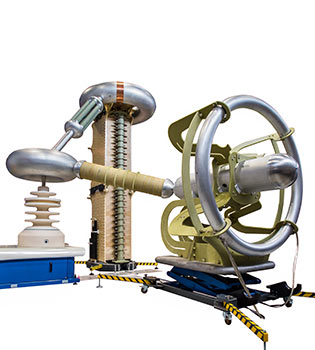

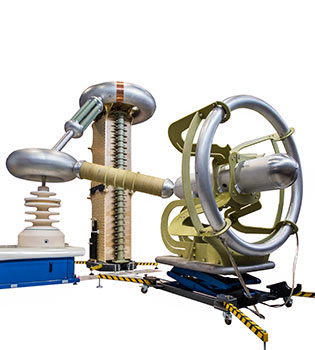

Lightning Simulator

ITOPP has developed a device to simulate the effects of direct and indirect lightning strikes. The use of this simulator can be adapted to fit a variety of specifications.

ITOPP designs and manufactures ready-to-use test equipment, in line with existing standards or built to meet specific customer performance requirements (electrical, environmental or requirements pertaining to size or mobility).

ITOPP’s technologies are ideal for testing aircraft resistance to lightning strikes. In particular, ITOPP's technologies make it possible to study the behaviors of composite materials, which react very differently than more regular metals during a lightning strike.

Airborne drone

Some of our relevant subsidiaries:

-

read more

With over 20 years of experience, ITOPP (formerly ITHPP) has become the French leader in high pulsed-power and high-power microwave technologies.

Driven by customer specifications, ITOPP designs and manufactures adapted and highly innovative systems linking these technologies to scientific research and also to civil and military applications.

High Pulsed-Power technologies allow for the amplification of electrical power delivery over a shorter burst period. Since energy is the product of power over time, by maintaining a constant flow of energy and reducing the duration of the pulse, it is possible to achieve powers in excess of one hundred Gigawatts.

High-Powered Microwaves are very highly charged electromagnetic pulsations capable of disturbing and even destroying electronic components used in today's increasingly complex systems. The interest in these high-powered microwaves are due to the vast array of uses, varying from more classic uses (such as Radar) to more advanced technologies, such as those used in Electronic Warfare.

- Website

- Location on map

- +33 5 65 33 43 30

ITOPP on ALCEN's website

Defense & Security Airborne drone

Defense & Security Simulation

-

read more

ADROHA develops and manufactures light fixed-wing and multi-rotor aerial drone systems.

ADROHA offers a complete range of innovative UAV solutions for training and operational missions such as rapid reconnaissance (ISR), interception, targeting, and heavy-lift transport/dropping.

ADROHA aerial drones offer a high-performance tactical solution while providing easy and rapid integration in operational units.

Limited personnel training, logistical footprint, and associated costs of ADROHA systems result in a minimal Total Cost of Ownership (TCO).

The UAV systems offered by ADROHA have been proven in operational environments....

ADROHA on ALCEN's website

Airborne Drone Neutralization

ITOPP manufactures drone neutralization systems based on high-powered microwaves, effective against autonomous drones and at a distance of several hundred meters. These transportable systems provide a direct response to the security threats generated by the proliferation of UAV’s, and complement already existing detection solutions.

Customized Drone

ADROHA designs and manufactures custom fixed-wing and mobile-wing systems.

Its disruptive approach allows it to offer operational solutions with short development cycles (3 to 6 months).

ADROHA notably developed the BlackBird multi-rotor drone, which provides a deep-sea submarine with the tactical vision of a UAV. This work was carried out in collaboration with ALSEAMAR company of ALCEN group.

ADROHA offers systems tailored for rapid vector projection on fixed-wing and multi-rotor systems.

Fixed-Wing Drone Range

ADROHA produces a range of fixed-wing drones to meet the needs of armed forces in the areas of rapid reconnaissance, target training, and interception.

The ADROHA fixed-wing range offers a suitable solution for all training needs and missions requiring high elongation and high endurance.

ADROHA systems are extremely simple to use and deploy at the field, while maintaining a minimal total cost of ownership.

Multi-Rotor Drone Range

ADROHA designs and manufactures multi-rotor drones for operational needs with a small logistical footprint.

The ADROHA range of lightweight multi-rotors is suitable for specific reconnaissance and rapid interception missions.

ADROHA has also developed a range of multicopter carriers for transporting and dropping heavy loads up to 30 kg.

ADROHA systems are extremely simple to use and deploy at the field, while maintaining a minimal total cost of ownership.

Mechanical & electronic components

Some of our relevant subsidiaries:

-

read more

ADR designs and manufactures high-precision ball bearings in a wide range of sizes (from 1 mm in bore size to 330 mm in outside diameter).

These highly sensitive bearings are found in viewfinders, gyro-stabilized systems, optoelectronic and avionics equipment, infrared pointers, encoders, motors, etc.

As a subsystems developer, ADR develops and offers integrated technical solutions, incorporating a variety of different functions to the bearings.

ADR also designs and produces actuators specifically adapted to highly complex systems.

- Website

- Location on map

- +33 1 64 70 59 50

ADR on ALCEN's website

Defense & Security Mechanical & electronic components

Energy Oil & Gas

Aeronautics & Space Mechanical components

-

read more

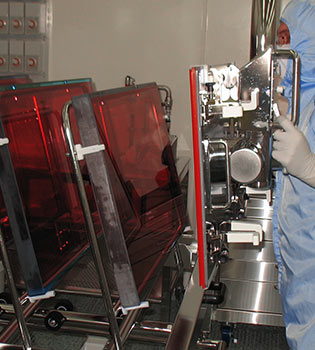

Bringing together the expertise and means of four ALCEN subsidiaries, ALSYMEX offers its clients solutions and services with high added value:

- Feasibility studies

- Engineering: machining, welding, vacuum

- Detailed design: mechanical engineering, thermo-mechanics, seismicity, vacuum, optics

- Production of high-precision mechanical and optomechanical assemblies: boilerwork, joint welding, machining

- Integration of complex systems in ISO 5 to ISO 8 cleanrooms

- Non-destructive testing

- On-site installation

- Maintenance of mechanical, optomechanical, vacuum and high voltage systems for large scientific instruments and nuclear-capable sites

- Large program management

ALSYMEX operates in the fields of Defense, Energy, Aeronautics and Large Research Infrastructures.

- Website

- Location on map

- +33 5 56 13 84 44

ALSYMEX on ALCEN's website

Defense & Security Engineering, Maintenance & Services

Defense & Security Mechanical & electronic components

Energy Nuclear

Energy Engineering, Maintenance & Services

Energy Oil & Gas

Aeronautics & Space Engineering & Maintenance

Aeronautics & Space Mechanical components

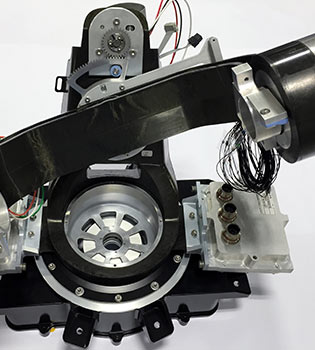

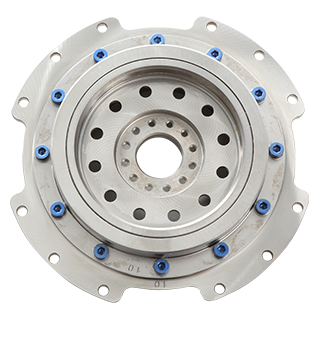

Electromechanical Precision Subassemblies

ADR designs and manufactures complete electromechanical subassemblies using its technical skills and expertise in the field of optronics.

In order to improve compactness and performance, ADR integrates the electromechanical functions as close as possible to the bearings with the engines, encoders, structures, wiring, electronics, connectors, etc.

ADR combines the quality of its production facilities with its skills and expertise in precision assembly, guaranteeing repeatability and full control of subassembly performance.

ADR has widely demonstrated its abilities in this field, designing and manufacturing electromechanical positioners with carbon composite structures, motorized bearings, hollow-shaft servomotors, etc.

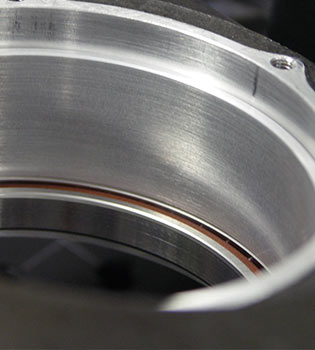

High-Precision Ball Bearings

Miniature and annular bearings for specific environments

ADR designs and manufactures a wide range of high-precision ball bearings that comply with the most demanding technical specifications and are EN9100 certified.

The materials, liquid or solid lubricants and manufacturing processes are qualified and field proven. The range of ADR's bearings is vast: from 1 to 330 mm and up to ABEC 9 (ISO 2). They guarantee high reliability and resistance in the most restrictive environments: vibration, thermal, climatic, speed, etc.

ADR ball bearings are present in a large variety of equipment incorporating observation or guidance functions (optronics, viewfinders, navigation, missiles, etc.).

Integrated Bearings

ADR designs and manufactures a line of preloaded duplex ball bearings, giving the best compromise of stiffness and friction torque while optimizing the weight, dimensions and cost of the equipment.

This special design guarantees a stable system over a wide temperature range, limiting faults and geometric dispersions. With assembly and final inspections in a clean room, it ensures high precision and high positioning repeatability. ADR also offers tested sealing solutions, ensuring management of friction torque and leak rate.

These integrated bearings are used by major defense contractors around the world, for products such as gyrostabilized pods, sights, observation systems, and more.

Safety Mechanisms

ALSYMEX designs and manufactures a line of effective safety device solutions.

The ALSYMEX "safety device" unit works on various types of components:

- Aeronautical non-return valves

- Subsea safety valves

- Tank lids

Engineering, Maintenance & Services

Some of our relevant subsidiaries:

-

read more

ALSEAMAR designs, manufactures and operates naval and underwater products (subsea gliders, unmanned surface vehicles, swimmer delivery vehicles, underwater acoustic positioning equipment, naval radio communication systems, deep-water pure syntactic foam buoyancy products) and is a provider of numerous services (underwater and marine monitoring, inspection, maintenance and upgrade of naval weapon systems, training, and more).

ALSEAMAR's commitment to its customers relies on the high skills and reactivity of its roughly 100 members of personnel, including over 50 engineers and 30 senior technicians, ready to be mobilized for projects around the world.

Main Product Lines

- Subsea and surface robotics

- Radio frequency communications

- Subsea passive acoustics

- Subsea vehicles for divers

- Deep-water syntactic foam buoyancy materials

Main Services

- Life-extension services for orphan and/or aged naval systems

- Marine survey services using subsea gliders and unmanned surface drones

- Localization of aircraft or submarine black boxes in the event of an accident at sea

- Training and instruction

ALSEAMAR on ALCEN's website

Defense & Security Naval & Submarine

Defense & Security Engineering, Maintenance & Services

Energy Oil & Gas

Aeronautics & Space Engineering & Maintenance

-

read more

Bringing together the expertise and means of four ALCEN subsidiaries, ALSYMEX offers its clients solutions and services with high added value:

- Feasibility studies

- Engineering: machining, welding, vacuum

- Detailed design: mechanical engineering, thermo-mechanics, seismicity, vacuum, optics

- Production of high-precision mechanical and optomechanical assemblies: boilerwork, joint welding, machining

- Integration of complex systems in ISO 5 to ISO 8 cleanrooms

- Non-destructive testing

- On-site installation

- Maintenance of mechanical, optomechanical, vacuum and high voltage systems for large scientific instruments and nuclear-capable sites

- Large program management

ALSYMEX operates in the fields of Defense, Energy, Aeronautics and Large Research Infrastructures.

- Website

- Location on map

- +33 5 56 13 84 44

ALSYMEX on ALCEN's website

Defense & Security Engineering, Maintenance & Services

Defense & Security Mechanical & electronic components

Energy Nuclear

Energy Engineering, Maintenance & Services

Energy Oil & Gas

Aeronautics & Space Engineering & Maintenance

Aeronautics & Space Mechanical components

-

read more

With over 30 years of experience, LERITY (formerly LHERITIER) designs and manufactures complex cameras and vision systems, capturing images in the visible spectrum. Thanks to an ambitious policy of research & development, notably in the field of sensors and algorithms for real-time image enhancement, LERITY has reached a level of excellence in image restitution quality, and is today a recognized expert in low light levels.

LERITY is both an OEM for important international actors in optronics & vision systems and an optronics company in itself at the forefront of innovation, notably in active imaging technology via its CAT EYE camera and CAT EYE series of vision systems. LERITY can easily and fluidly adapt itself to the specific needs of its customers: whether they be industrials, security companies or military forces.

Its reputation has notably been established in 3 markets, both in France and internationally:

- Defense & Security: Day channel for vehicle-mounted optronics system, perimeter vision and wide area surveillance, cameras for submarine periscope, day/night coastal surveillance, shooting range metrology, day/night vision cameras with CAT EYE active imaging

- Aeronautics: Head-up display cameras (HUD), taxiway cameras, cargo-monitoring cameras, cockpit cameras (CIRS)…

- Railway: On-board retrovision systems (SNCF), guidance for tramways and buses, camera assistance in automatic driving

- Website

- Location on map

- +33 1 34 24 38 20

LERITY on ALCEN's website

Defense & Security Vision, Inspection & Localization

Defense & Security Engineering, Maintenance & Services

Energy Nuclear

Aeronautics & Space Vision & Inspection

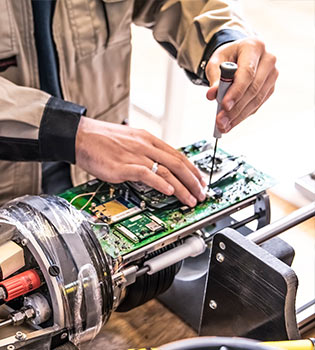

Lifetime Extension

ALSEAMAR has a wide range of services for modernizing naval systems to increase service life, improve performance and anticipate technological changes.

The ALSEAMAR teams have recognized obsolescence management skills and use modernization and reverse-engineering methodologies, in particular for "orphan" systems.

ALSEAMAR's skills on board ships or submarines cover alarm systems, radar, sonar, radiocommunication systems, instrumentation and control systems, and all types of subsea vehicles.

For each case, ALSEAMAR is able to offer a turnkey solution to extend the service life of this equipment while incorporating new features.

Maintenance in Naval Operational Conditions

ALSEAMAR provides maintenance and repair services including: - the execution of configuration states and equipment inventories, - the drafting of maintenance plans and change orders, - the dimensioning of batches of spare parts and their supply, - the design of special tooling, and - the operation of work sites.

ALSEAMAR works on its clients' sites, in France and overseas, with multidisciplinary teams. It can also turn to local subcontractors depending on the types of operations needed (mechanical, electromechanical, electronic, surface treatment, hydraulics, etc.).

A leading operator for the French and foreign navies for Maintenance in Operational Conditions contracts, with high demands in terms of availability, ALSEAMAR offers a wide range of services: Zero state, preventive and corrective maintenance, hotline, design basis and spares management, CMMS, etc.

Automation and Robotization of Industrial Processes

From pre-project engineering to commissioning, ALSYMEX offers a comprehensive automation and robotization service for equipment, machines, process lines, etc. that are already in existence, are just being designed or are already under development.

Design and Production of Control Systems

ALSYMEX designs and manufactures automation, control and piloting systems (control panels, HMI type interfaces).

The main area of expertise that sets ALSYMEX apart is its mastery of high availability safety automation using redundant safety PLCs up to SIL3.

Mechanical Design and Production

ALSYMEX offers its customers solutions that combine machining, assembly — in particular by welding — of large, high-precision mechanical components and subassemblies.

ALSYMEX is an industrial company that brings together six former subsidiaries of the ALCEN Group: ALSYOM, ALYNOX, ATMOSTAT, CHAMPALLE, SEIV and SIRATECH.

Some key ALSYMEX projects:

- Manufacturing of the New Generation Dagaie System decoy launcher

- Manufacturing of the shells of Armored Infantry Combat Vehicles

- Design, manufacturing and qualification of the new SYLENA MK2 decoy launcher systems

Mechanical Design and Production

ALSYMEX offers an integration service for various materials, including exotic materials, during the design of complex systems. Lengthy, solid experience acquired in major projects in the Space, Aeronautical and Fusion sectors means that it can guarantee full management of property, personal and environmental protection engineering.

ALSYMEX experts intervene in the early stages of a project, from the architecture of the client solution (particularly in the infrastructure and product interface definition and operational checking phases in the user environment) to systems and equipment support engineering, throughout the solution's life cycle.

Operational Maintenance of Simulation Systems

Due to its experience producing critical components for various machines, and with its ability to deploy multidisciplinary teams on site, ALSYMEX is heavily involved in the maintenance in operational conditions of the French nuclear simulation program.

In addition to having maintained in operational conditions the Laser Integration Line of the Megajoule Laser facility (LMJ), ALSYMEX is also responsible for the preventive and corrective maintenance of the experiment hall equipment and amplification sections of the LMJ, as well as that of the AIRIX flash radiography machine. Combining its expertise with that of other companies in the ALCEN Group, such as IRELEC and ITHPP, ALSYMEX works on all of the constituent subassemblies of these complex machines:

- Mechanical, optomechanical and vacuum systems

- Instrumentation

- High Voltage and electrotechnical systems

- Control command and electronic systems

Operational Maintenance for Vision Systems

LERITY operates in the optics and electronics field for the maintenance or modernization of cameras and vision systems.

Thanks to its very high level of expertise and its extensive resources, LERITY is able to ensure the appraisal, repair, obsolescence management and retro-engineering of aged systems (typically transformation of analogue visible channels into Full HD digital format).

LERITY offers either retrofitting or modernization of optoelectronic equipment for different types of obsolescence, and using an "FFF" (Fit-Form-Function) approach in line with the latest technological standards, and with an eye to cost-saving efforts throughout the equipment's life cycle.

LERITY has guaranteed the modernization of visible channels of combat systems, from analogue cameras to the digital standard, and modernization of submarine periscopes.