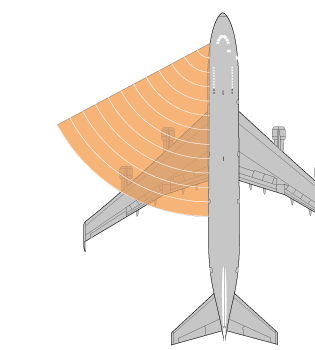

ALSEAMAR operates 24/7 in the event of air accidents to quickly locate black boxes, covering every sea in the world.

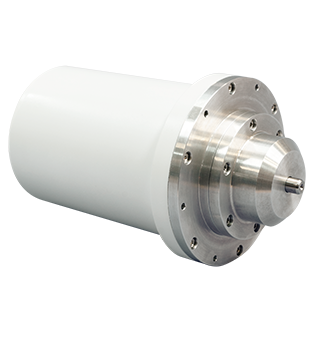

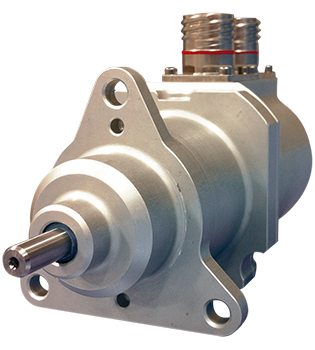

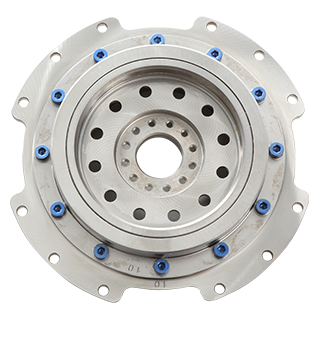

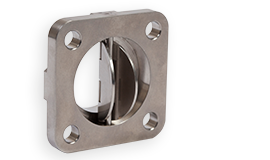

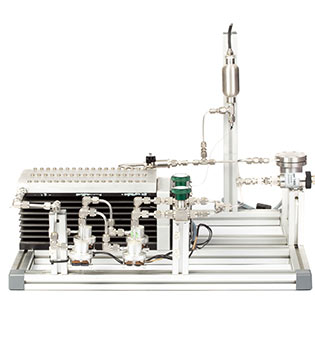

To do so, the company uses its 20 years of experience in subsea acoustics and the two long-distance acoustic detection systems ALSEAMAR has developed and operates in the event of accidents, the DETECTOR-1000 and the DETECTOR-6000.

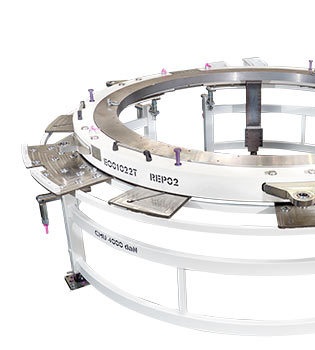

The turnkey service offered by ALSEAMAR includes: - dispatch to the site of equipment and personnel to conduct searches, - deployment and recovery of DETECTOR, and - issuance of a mission report.

Submerged 1,000 m under the sea, the DETECTORs are capable of detecting and distinguishing the low noise levels of a flight recorder from the background sea noise at up to a depth of 4,000 meters.

ALSEAMAR successfully intervened in 2016 to locate the black boxes of EgyptAir flight MS804 at a depth of 3,000 m in the Mediterranean sea. The company has also intervened successfully in Sharm El Sheikh (Red Sea) and Sochi (Black Sea).

The location process can take a few hours or a few days, depending on the size of the search area and the meteorological conditions.