ALSEAMAR uses innovative surface drones and subsea gliders for independent observation of the marine environment.

These turnkey services are used to collect and analyze data for a wide range of missions: scientific research, oceanography, marine environment protection, water quality monitoring, recording of ambient noise, intervention for hydrocarbon leaks, detection of natural gas or oil leaks, baseline studies and metocean operations for oil operators.

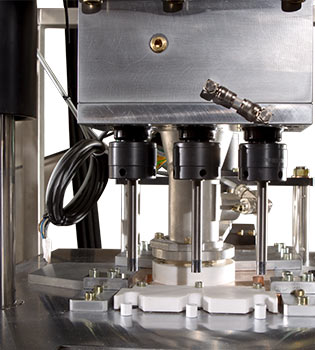

The SeaExplorer subsea glider is a detection platform perfectly suited to these operations. A high-endurance, autonomous subsea drone, it was designed to collect data over large areas (thousands of kilometres), over long periods (months) and at great depths (1,000 m) thanks to the integration of a wide range of specific sensors.

Controlled from land, propelled by variations in buoyancy, the vehicle glides silently along the water column collecting physical, chemical, biological and/or acoustic data, depending on the mission assigned.

The added value of the SeaExplorer lies in the low operation cost compared to the vessels or other means traditionally mobilized for the same type of mission.